Self-Pierce Riveting (SPR)

Self-Piercing Rivet Solutions

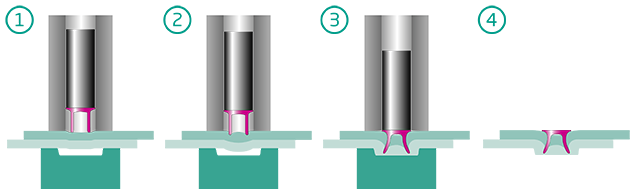

The metal-layers are placed between the stripper and the die. With the motion of the punch, the rivet cuts through the first layer. Based on the shape of the die and the rivet, the rivet spreads into the die side layer. Check out the diagram below for a visual on how the self-pierce riveting (SPR) process works.

Fixing

Application of rivet

Deformation of rivet and joined parts

Return stroke

For more information on our self-piercing rivet solutions, contact TOX® PRESSOTECHNIK today!

Contact GB: +44 1785 904667 Contact form |

Cookie Information We use cookies to give you the best possible experience when using our website. You can block or regulate the use of cookies by adjusting your browser settings accordingly. |