The separation by steel rule cutting is characterized by the penetration of a wedge-shaped steel into the material and forcing it apart. Steel rule cutting is mainly used on softer materials and for trimming.

Punching, Piercing & Shearing

System technology

TOX® PRESSTOECHNIK has comprehensive know-how in punching technology - from simple punching presses, to highly engineered punching systems.

Do you want holes and notches, custom shapes, single or multiple punched holes, or punching, forming and calibrating in one stroke?

Whether sheet metal, plastic, cardboard, textiles or foils - TOX® PRESSOTECHNIK develops individual solutions with our customers.

For these customized applications, specific solutions are assembled from the standardized components of our modular system:

The required punching technology is designed, tested and inspected in cooperation with the TOX® owned development and design laboratory. Manufacturing and assembly also take place at the headquarters in Weingarten, as well as at our five other production sites worldwide. Support during implementation as well as further training courses are available on request.

Our quality approach offers you the greatest added value in the execution of punching system technologies in our complete punching machines and systems.

The modular system of TOX® PRESSOTECHNIK allows complete solutions for almost any punching application.

By selecting the appropriate components, the ideal system for a specific application is assembled. The components thereby form the basis to meet your requirements:

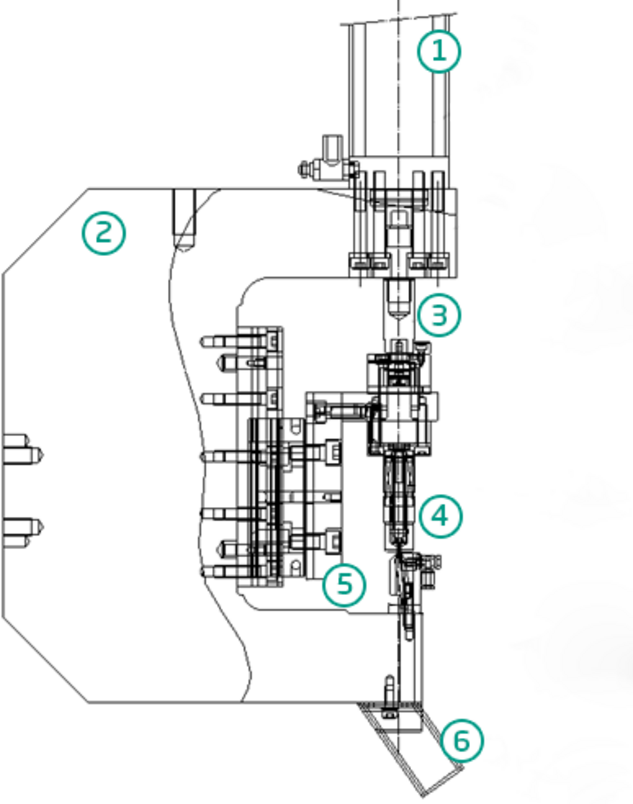

Press frame or tong

Die coupling

Punching tooling consisting of punch and die

Guide rail and carriage for precise alignment

Removal of the slug

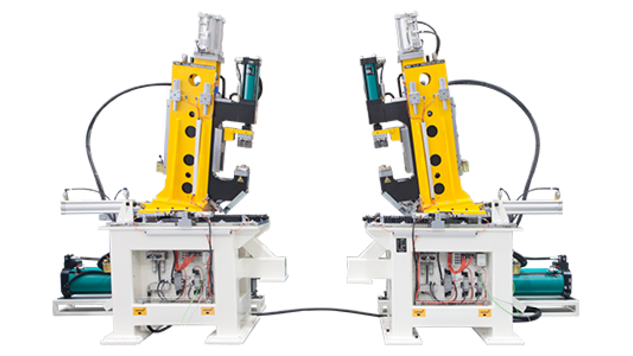

The equipment is specially designed for two punching operations on one shock tower. For the workpiece, 8 holes are punched – four on the left and four on the right side with each cycle of the machine. Two, simultaneously-operating TOX®-Presses are used, each driven by an X-ES pressure intensifier with TOX®-Hydraulic cylinder HZL. The process is controlled by the customer's PLC, which ensures optimum integration into the assembly line.

With low impact forces and the ability to automatically activate the power stroke, TOX®-Powerpackages are ideal for punching shock tower.

Technical data:

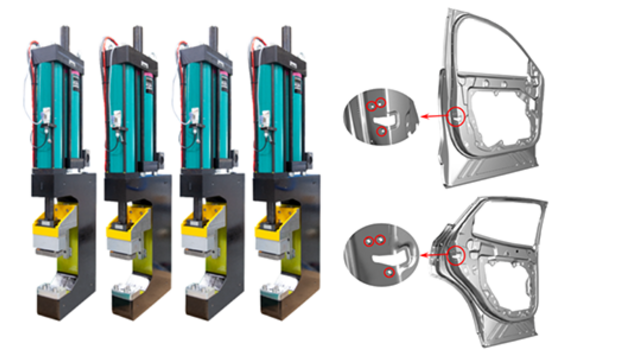

For the efficient hole punching of car doors, a custom customer solution was developed. Driven by four TOX®-Powerpackages type Typ Q-K, a total of 12 holes are punched on 4 car doors in one machine cycle. After manually loading of the parts, the system initiates via the two-hand controller. Each system is operated by one of the four integrated safety controls type ST ES, while the return stroke is controlled by means of a pressure switch.

Technical data:

To ensure an efficient, robot-carried punching process, a custom system was developed. The application is for the punching of a side wall in the automotive sector. The robot tongs were equipped with the TOX®-Powerpackage type Q-K whose pneumatics are initiated by an "in-position" signal of the customer's PLC. With each punching press cycle, a hole of 6 mm diameter is punched. The robot takt time is approximately 5 seconds. The controller type ST ES is used as a safety control.

Technical data:

This application in the automotive sector required particularly high press forces and a large tool workspace. In order to punch panoramic roof panels, a customized system was designed. The basis is a TOX®-Universal subframe and a 4-column press from our MAG series with a bed width of 2,880 mm. Two pneumohydraulic TOX®-Powerpackages type EKSD, which together generate approximately 2,000 kN press force (964 kN max. per Powerpackage), function as the drives. The control system was equipped with all necessary, bus-capable connections in order to be able to operate the press system fully automatically with integrated loading and unloading robots. As implemented, integration into an automated production line is easily accomplished. The multifunctional punching die includes an upper die with 26 shearing punches and a lower die with 26 dies. This die can be completely removed and retooled if required. All punching operations are performed in one stroke, which ensures the highest accuracy.

Technical data:

According to DIN 8588, splitting or piercing is classified as the non-cutting mechanical separation of parts with the help of cutting edges. This procedure can produce high quantities of precise and complicated metal parts (or other materials) in a very short time.

This procedure is likely used for the further processing of semi-finished products made of sheet metal, partially-finished parts in the automobile industry or plastic parts in the white goods industry.

Principal groups of piercing

Separation by cutting with steel rule, cutting with two approaching steels, and shearing.

Steel rule cutting

The separation by steel rule cutting is characterized by the penetration of a wedge-shaped steel into the material and forcing it apart. Steel rule cutting is mainly used on softer materials and for trimming.

Cutting with two approaching steels

Contrary to steel rule cutting, two wedge-shaped steels penetrate the material. Pinching with a pair of tongs is an example for this kind of separation. This process is also mainly used for on softer materials and for trimming.

Shearing

[1] Punch

[2] Piece part

[3] Die

[a] Die clearance

[F] Force

Shearing is the most frequently used process in industrial and commercial applications because it is very productive. This process occurs when two cutting tools move (at least one) against each other. The material parts of the cutting surface drive against each other. This process needs three steps:

1. Elastic deflection

2. Plastic flowing

3. Cracking

Because of the cutting force, the sheet elastically deflects, is then plastically deformed and starts flowing. Finally, cracking takes place and the material breaks i.e. shears off. When shearing, generally a difference is made between the opened and the closed cut. An example for the open cut is the cutting off of a metal strip (like cutting with scissors). If the total cutting line is within the piece part, this will be a closed cut.

A correct die clearance is required for an optimal shearing effect, high cutting quality and long serviceable life of the tools. The required die clearance depends on the shear strength and the thickness of the sheet. In the TOX®-Piercing Systems brochure, a table shows general values of the die clearance.

Sequence of a piercing process

The tool is mounted to a press or a piercing bow.

The upper tool with the cutting punch is moved towards the workpiece by the drive

The spring-mounted stripper clamps on the piece part, the springs are compressed.

The cutting punch touches the part, the drive further builds-up the force.

The cutting punch penetrates into the sheet. The penetration depth depends on the material characteristics and the thickness of the piece part along with optimal die clearance.

The piercing slug breaks through into the die and causes the sudden release of the driving system energy. This release of pressure is called “cutting impact”.

The punching slug is discharged.

A good cut quality of the tool depends on:

The design configuration and operating mode of a cutting tool have a decisive influence on the production result. Among others, a differentiation is made according to their type of guidance. There are three essential types of guidance for cutting tools.

1. Free cutting tools

2. Plate-guided tools

3. Column-guided or guided upper tools - rams through guide rail/guide carriage

Calculation of punching machine forces

To define the size of a system the calculation of the cutting force is necessary.

Fs= ls x s x ks

Fs = cutting force

ls = cutting length

s = sheet thickness

ks = shear strength (approx. 0.8 x Rm)

Rm = tensile strength of the material

For the design of tongs or tools, a safety value of at least 20% must be added.

Rake angled punches can considerably reduce the cutting force.

If the total cutting force exceeds 25 kN, special design measures must be taken into consideration.

Equipment for Punching Applications

We offer a range of machines for punching applications, including:

Let us know if we can help you to get a quote on this equipment.

Contact GB: +44 1785 904667 Contact form |

Cookie Information We use cookies to give you the best possible experience when using our website. You can block or regulate the use of cookies by adjusting your browser settings accordingly. |